Manufacturing – ERP

We build manufacturing software solutions that bridge the gap between businesses and their customers, enabling them to streamline production management, inventory tracking, and data analysis for seamless manufacturing operations.

Trusted by 50+ Happy Clients & Companies

Manufacturing Application Solution

Transform the way you manage production, inventory, and operations with custom manufacturing application solutions. From an ERP system to streamline workflows, a website to showcase your capabilities, or a mobile app for real-time monitoring, we can build solutions tailored to your manufacturing needs.

Whether you’re a growing business or an established enterprise, our secure and scalable solutions enable seamless digital transformation. Discover the right solution to enhance efficiency, whether for local operations or global expansion.

Our applications adhere to industry standards, ensuring data accuracy and security. With continuous support, you can rely on us whenever assistance is needed.

Enterprise Resource Planning (ERP) Applications

Manufacturing Execution Systems (MES)

Supply Chain Management (SCM) Applications

Product Lifecycle Management (PLM) Applications

Manufacturing Software Development Cost

| Types of Manufacturing Application | Manufacturing Application with Basic Features | Manufacturing Application with Minimum Required Features | Feature Rich Manufacturing Application |

| Design | Simple UI | Interactive IJI | Rich Ul |

| Features | Basic | Minimum Required | Feature Rich |

| Number of Pages | Few | Less than 50 | More than 50 |

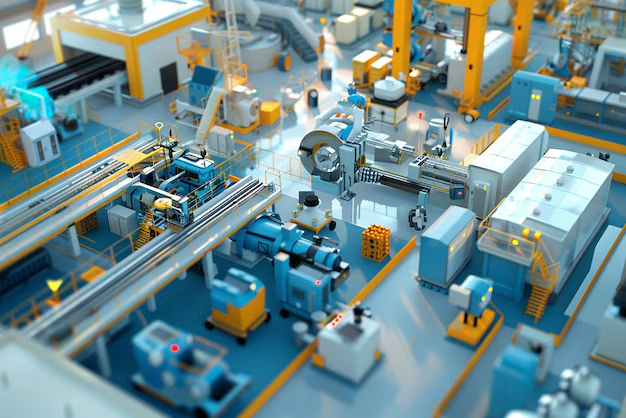

Advancing Manufacturing with Technology

Leveraging Advanced Technology for Competitive and Efficient Modern Manufacturing

Technology in modern manufacturing boosts productivity, cuts costs, and improves product quality. With tools like robotics, IoT, AI, and automation, manufacturers can streamline operations, monitor performance in real time, and collect data for informed decision-making. ERP systems synchronize production and business processes, ensuring efficient resource allocation, inventory management, and planning. These technologies enable greater precision, quicker turnaround times, and enhanced responsiveness to market demands. By embracing these advancements, manufacturers achieve improved efficiency, flexibility, and competitiveness

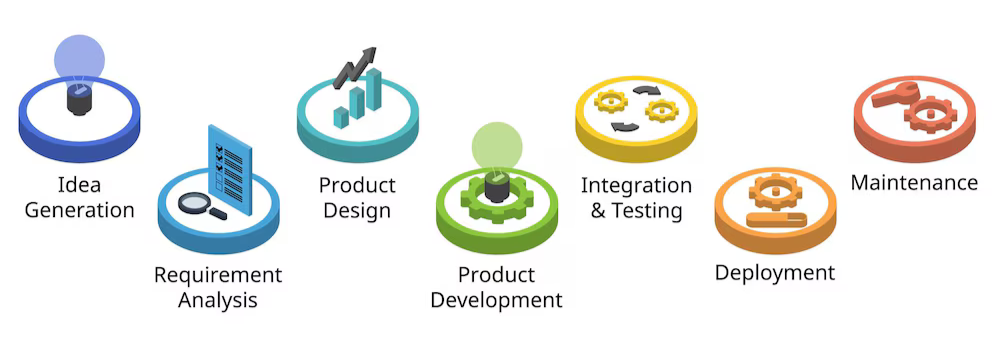

Software Development Process for

Manufacturing Industry

Flexible Hiring Model for Insurance

Software Development

Hourly Based

- Pay-as-you-go

- On-demand flexibility

- Billing transparency

Fixed-Cost

- Well-defined scope

- Project timeline

Dedicated Team

- Exclusive project focus

- Customized expertise

- Resource adaptability

Time & Material

- Versatile model

- Pay for actual work

- Flexibility in changes

Streamlining Operations with Lean Manufacturing

Lean manufacturing, when integrated with ERP systems, provides businesses with significant benefits by optimizing processes, reducing waste, and improving overall efficiency.

Lean manufacturing focuses on:

- Reducing waste and maximizing value.

- Improving efficiency and lowering costs.

- Enhancing product quality and customer satisfaction.

- Streamlining operations and eliminating unnecessary activities.

Streamlining Manufacturing with ERP

ERP systems provide real-time data, allowing for better decision-making, resource allocation, and process improvements.

Optimizing Manufacturing with ERP

Technology in manufacturing drives operational excellence by optimizing efficiency, reducing costs, and enhancing product quality. ERP systems enable seamless integration of automation, IoT, robotics By leveraging these innovations, and superior product consistency, all while ensuring better compliance with industry standards.

Technologies & Platforms We Work With

Anguler

React

Vue

Next

NuxtJS

NodeJS

PHP

CodeIgniter

Nest

Laravel

DotNet

NodeJS

PHP

Ruby on Rails

Nest

WordPress

CodeIgniter

PHP

Ruby on Rails

Nest

Laravel

DotNet

DotNet

DotNet

NodeJS

PHP

Ruby on Rails

Nest

Laravel

DotNet

NodeJS

PHP

Ruby on Rails

Nest

Laravel

DotNet

We Ensure Seamless Collaboration

Signing the NDA

Signing the NDA is a formal agreement to keep shared information confidential.

Technical Lead Call

A call with a technical lead involves discussing technical details, or project updates.

Team Interview

An interview with the team is a session to assess a skills through team interaction.

Kickoff

A kickoff is the initial meeting to launch a project, outlining goals, roles, and timelines.

Testimonials

What Our Clients Say

We place a huge value on strong relationships. Our clients have faith in us. We always keep them ahead of their competitors by serving them top notch IT solutions.

Manufacturers Compete with Larger Enterprises

Helping Manufacturers Compete with Larger Enterprises through Innovation and Efficiency

Small manufacturers can compete with larger enterprises by focusing on niche markets, adopting agile and responsive production processes, and leveraging advanced technologies such as ERP to optimize efficiency. By maintaining exceptional product quality, fostering personalized customer relationships, and offering customized solutions, they create a unique value proposition. These strategies allow smaller manufacturers to be more flexible, responsive, and innovative, giving them a distinct competitive edge that larger organizations may struggle to replicate

Platforms We Use For Manufacturing Software Development

Manufacturing Integration

Effortless integration with the world's leading content management system (CMS).

Flexibility & Customization

Quickly customize your storefront with an extensive library of themes and plugins.

Scalability

Scale your store seamlessly as your business grows into a high-volume enterprise.

Widely Adopted

Connect with a vast community of store owners and developers, gaining access to comprehensive support and dependable solutions.

User-Friendly

Easy setup and management, designed for users with no extensive technical experience.

Cost-Effective

OpenCart is an open-source platform, offering a cost-effective solution for small to medium-sized businesses.

Multi-Store Functionality

Easily manage multiple storefronts from a single, centralized administrative dashboard.

Large Community

Take advantage of a wealth of support resources, tutorials, and extensions to enhance your experience.

Frequently asked questions (FAQ)

See the answers to some of our most commonly asked questions below.

What is the role of technology in modern manufacturing?

Technology in manufacturing enhances efficiency, reduces costs, and improves product quality. Innovations like automation, IoT, robotics, and AI streamline production processes, enable real-time monitoring, and provide actionable insights for decision-making.

What are Manufacturing Execution Systems (MES), and why are they important?

MES are software systems that monitor and control production on the shop floor. They track operations, manage workflows, and ensure production aligns with quality standards, enabling manufacturers to optimize processes and minimize errors.

How does lean manufacturing benefit businesses?

Lean manufacturing focuses on minimizing waste and maximizing value in production. It improves efficiency, reduces costs, enhances product quality, and boosts customer satisfaction by streamlining operations and eliminating non-value-adding activities.

What is Industry 4.0, and how does it impact manufacturing?

Industry 4.0 refers to the integration of digital technologies like IoT, AI, and big data into manufacturing. It enables smart factories where machines communicate, processes are automated, and data drives decision-making, leading to higher efficiency and innovation.

How can small manufacturers compete with larger enterprises?

Small manufacturers can compete by focusing on niche markets, adopting agile processes, leveraging technology to enhance efficiency, and maintaining high-quality standards. Building strong customer relationships and offering customized solutions also provide a competitive edge.